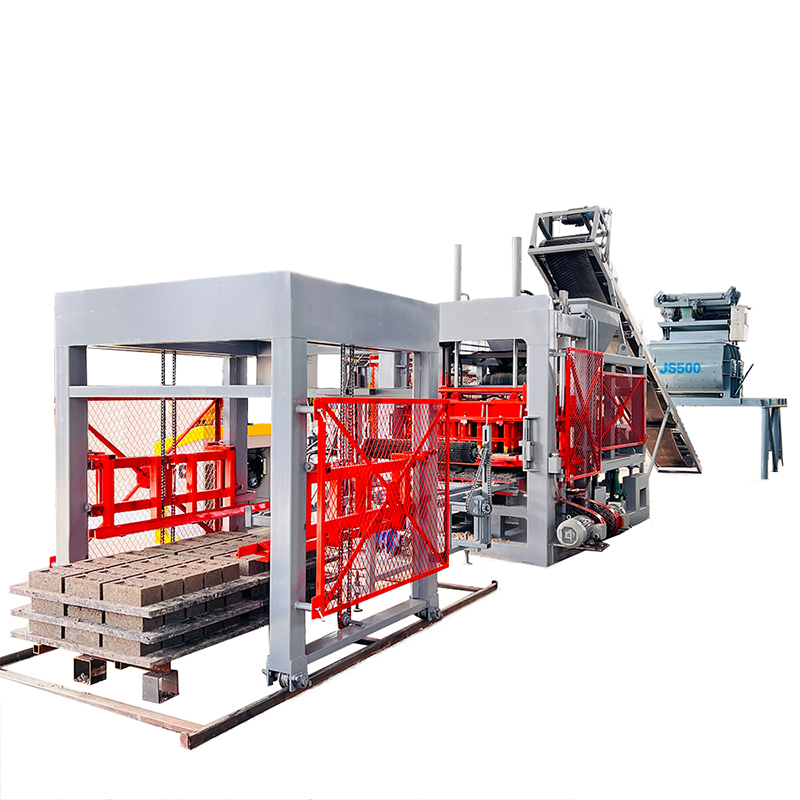

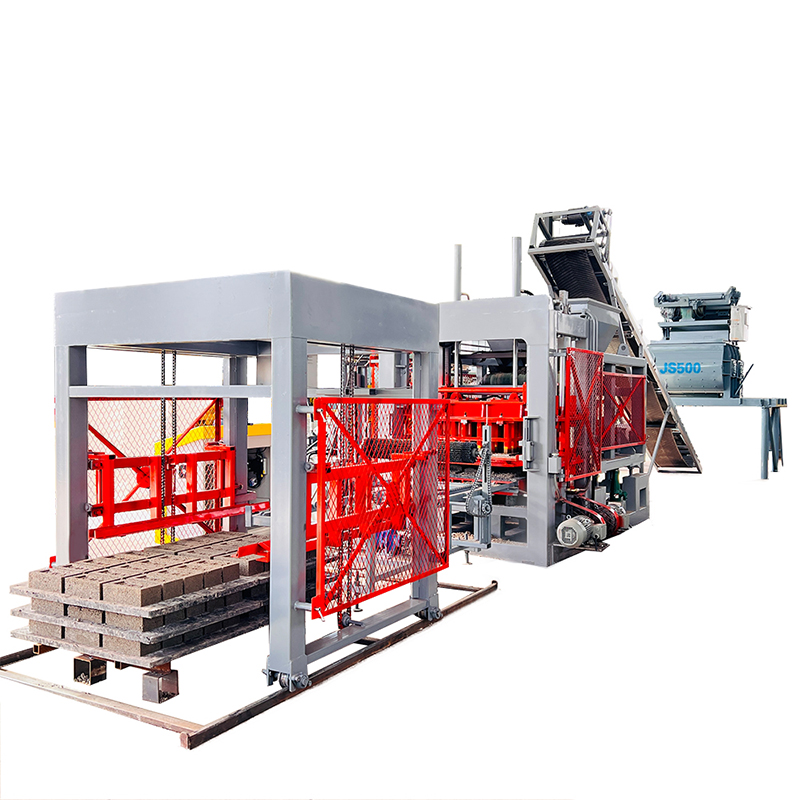

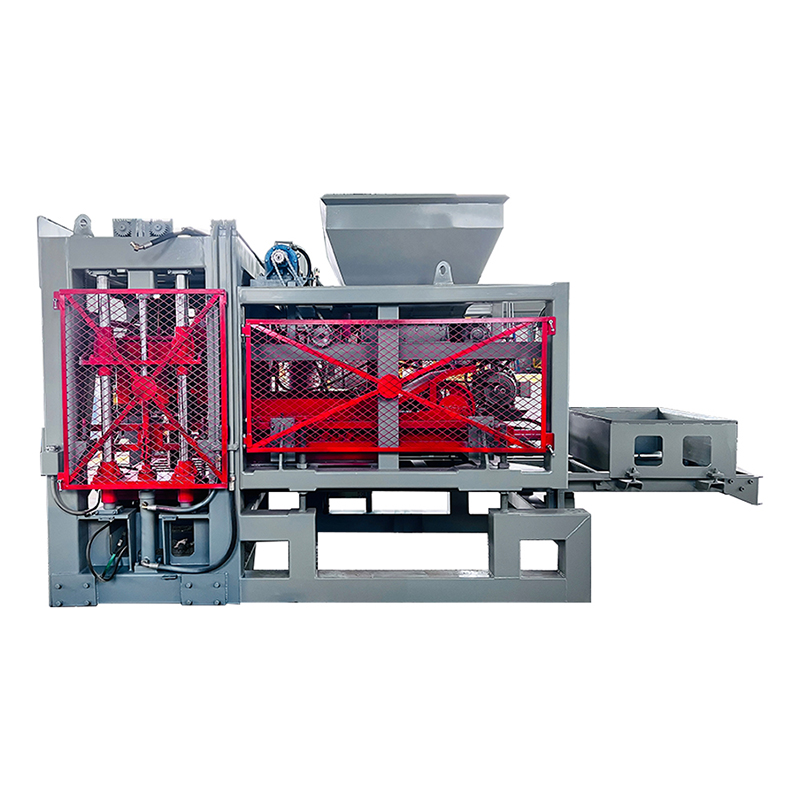

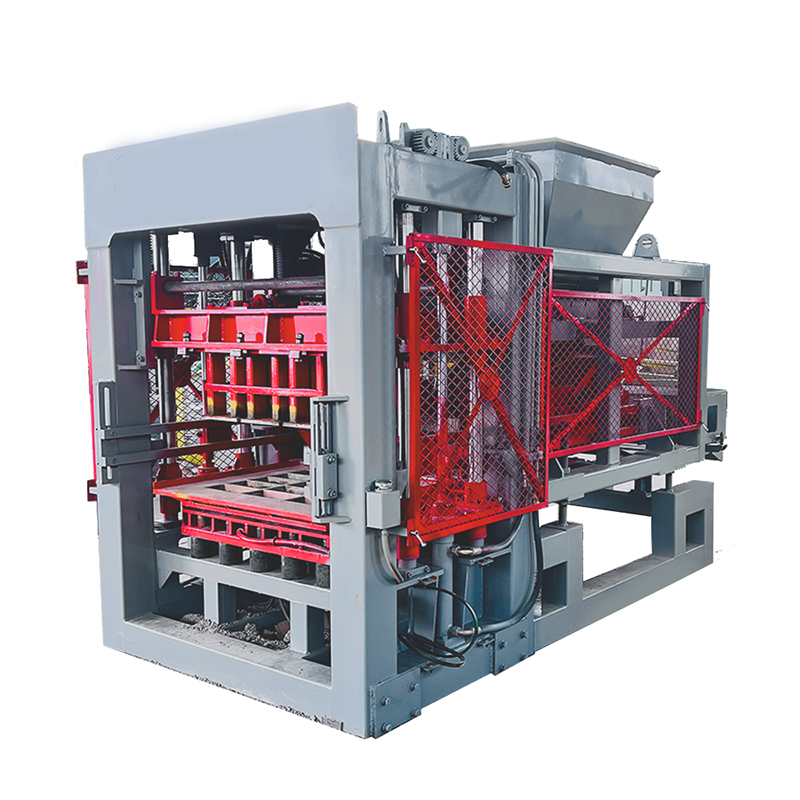

QT6-15 Hydraulic Cement Block Making Machine - Fully Automatic Solutions

QT6-15 block making machinery full automatic is one machine with multifunction. Changing molds can produce various kinds of specification porous bricks, standard bricks, hollow bricks, with a double material-feeding machine can produce all kinds of thecolored road bricks, grassland bricks, and slope protection bricks etc.

Product Description

1- QT6-15 Fully Automatic Stacking Brick Making Machine Plant use PLC intelligent control, make the man-machine interface as true, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function.

2- Can produce the paver block with or without color on the surface, if need color, should use the face-color material feeding device.

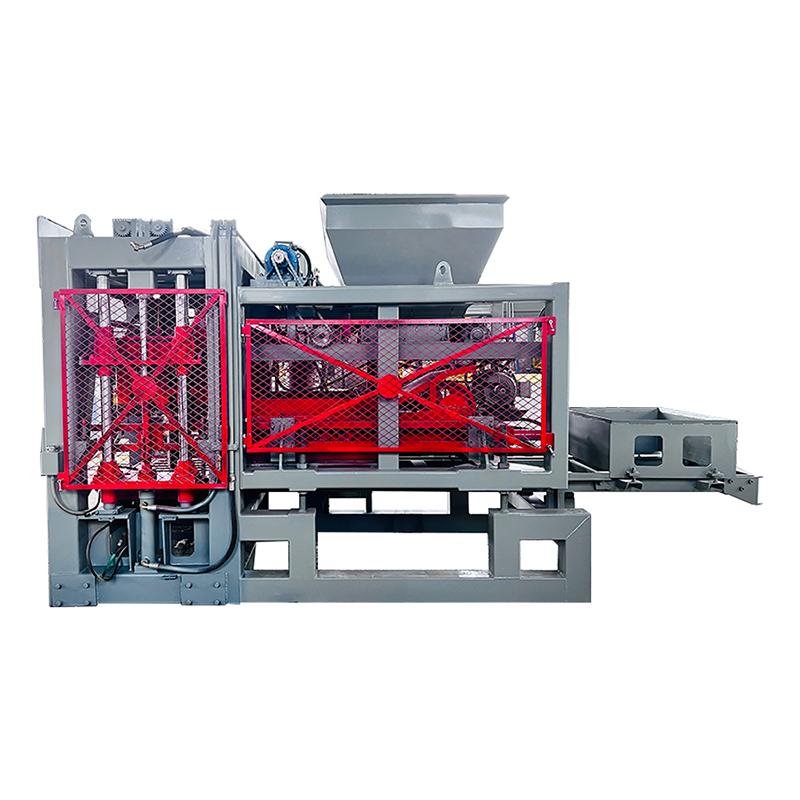

3- Through mold-releasing oil cylinder, the mold box was locked into the vibration table with high rigidity to reach the synchronous vibration, so that the concrete can be fluidified and exhausted in two or three seconds to ensure the high-density,especially suitable to produce the standard blocks, which can be piled up immediately so that the pallet investment can be saved directly.

4- The unique forcing charge system can make use of various kinds of industrial waste and material such as coal ash, cement, sand,stone, slag, and so on. The machine can severs several purposes and produce various specification standard bricks, concrete blocks, porous blocks, paving bricks etc just changing the mold.

Product Details

| Heat Treatment Block Mould Use heat treatment and line cutting technology to make sure accurate mold measurements and much longer service life. |  |

| Siemens PLC Station Siemens PLC control station, high reliability, low failure rate, powerful logic processing and data computing capability, long service life |  |

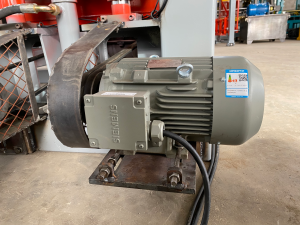

| Siemens Motor German orgrinal Siemens motor, low energy consumption, high protection level, longer service life than normal motors. |  |

|  |  |  |

Specification

Machine Dimensions | 3150*1900*2930mm |

Forming cycle | 15-20s |

Viberation force | 75KN |

Pallet size | 1100*700mm |

Main Vibration | platform vibration |

All Power | 29.7KW |

Molds | As customer’s requirement |

Rated pressure | 21MPA hydraulic pressure |

Finished blocks | hollow blocks, paver,solid blocks, curbstone,porous blocks,stander bricks etc |

Item | Block size(mm) | Pcs/ mould | Pcs/ Hours | Pcs/ 8 Hours |

Hollow block | 390x190x190 | 7 | 1260-1680 | 10080-13440 |

Hollow block | 390x140x190 | 8 | 1440-1920 | 11520-15360 |

Standard brick | 240*115*53 | 36 | 6480-8640 | 51840-69120 |

Paver bricks | 200x100x60 | 20 | 3600-4800 | 28800-38400 |

Customer Photos

Packing & Delivery

FAQ

- Who are we?

We are based in Hunan, China, start from 1999,sell to Africa(35%), South America(15%), South Asia(15%), Southeast Asia(10.00%), Mid East(5%),North America(5.00%), Eastern Asia(5.00%), Europe(5%),Central America(5%).

What is your pre-sale service?

1.Perfect 7*24 hours inquiry and professional consulting services.

2.Visit our factory anytime.

What is your on-sale service?

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

4.What is your After-Sales

1.Warranty period: 3 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.

5. What payment term and language can you accapt?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

The QT6-15 Hydraulic Cement Block Making Machine is at the forefront of modern construction technology, showcasing the pinnacle of automation and precision in block production. This fully automatic system is engineered with advanced PLC (Programmable Logic Controller) intelligent control, which seamlessly integrates the human-machine interface for intuitive operation. By utilizing sophisticated programming, the QT6-15 facilitates real-time monitoring and control of the production process, offering enhanced efficiency and reducing the potential for human error. The machine features a comprehensive logic control system, ensuring that each batch of hydraulic cement blocks meets strict quality standards while maximizing output. Incorporating state-of-the-art features, the QT6-15 is equipped with a malfunction diagnosis system that identifies and addresses issues promptly, reducing downtime significantly. Additionally, the remote control functionality empowers users to supervise the operation from a distance, making it an ideal solution for large-scale manufacturing environments. The flexibility of this hydraulic cement block making machine allows for the production of various block types, including solid, hollow, and interlocking bricks, catering to diverse construction needs. With a production capacity that can reach up to 6,000 blocks per day, the QT6-15 is designed to meet the demands of both small projects and large construction sites with ease. The QT6-15 Hydraulic Cement Block Making Machine not only maximizes production efficiency but also prioritizes sustainability. By utilizing hydraulic technology, the machine ensures minimal wastage of raw materials. Furthermore, the use of high-quality materials in construction guarantees the durability and longevity of the blocks produced. The machine’s energy-efficient design not only helps in reducing operational costs but also contributes to eco-friendly practices in the construction industry. As a pinnacle solution for those looking to invest in a hydraulic cement block making machine, the QT6-15 promises reliability, efficiency, and a significant return on investment. Experience the future of block production with Aichen's innovative solutions that redefine what’s possible in the realm of construction.