QT4-25 Automatic Concrete Block Machine – Superior Cement Brick Making Mould

QT4-25 can make all of above blocks by changing the moulds, we can also customize the moulds according to your block size.

Product Description

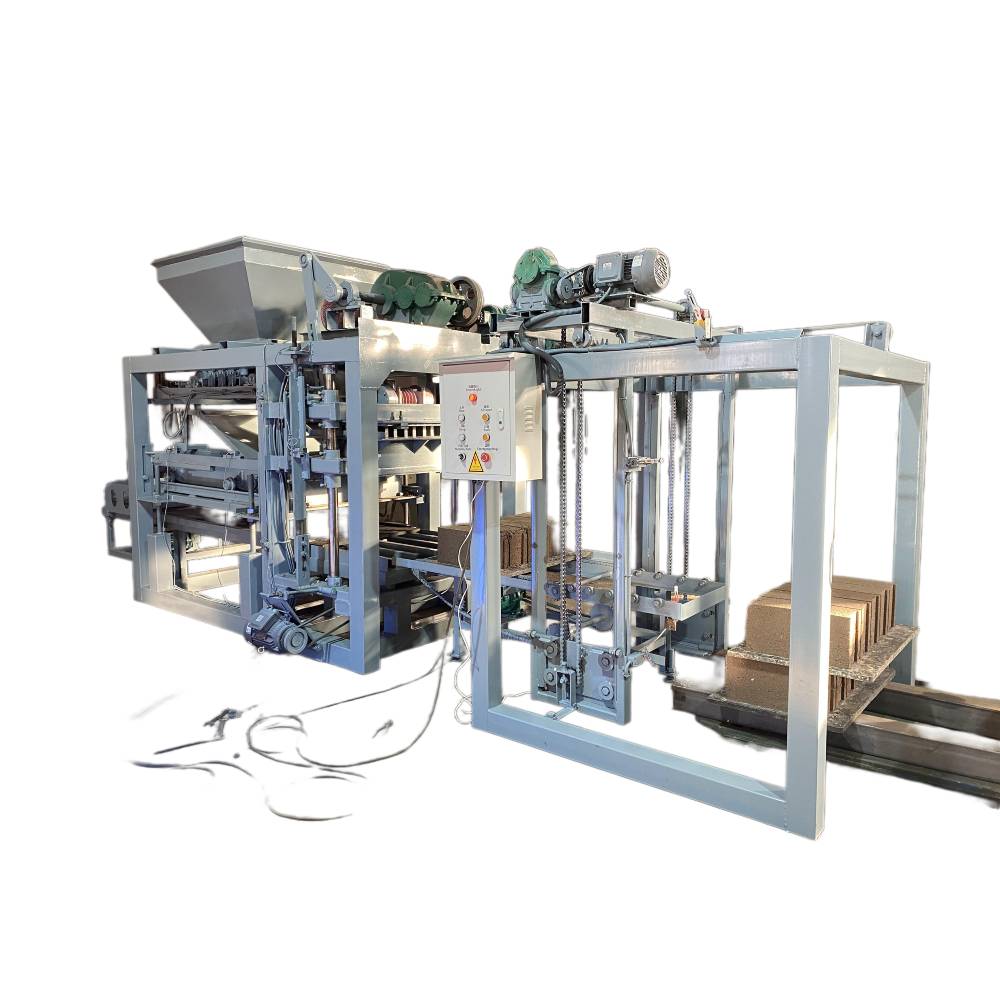

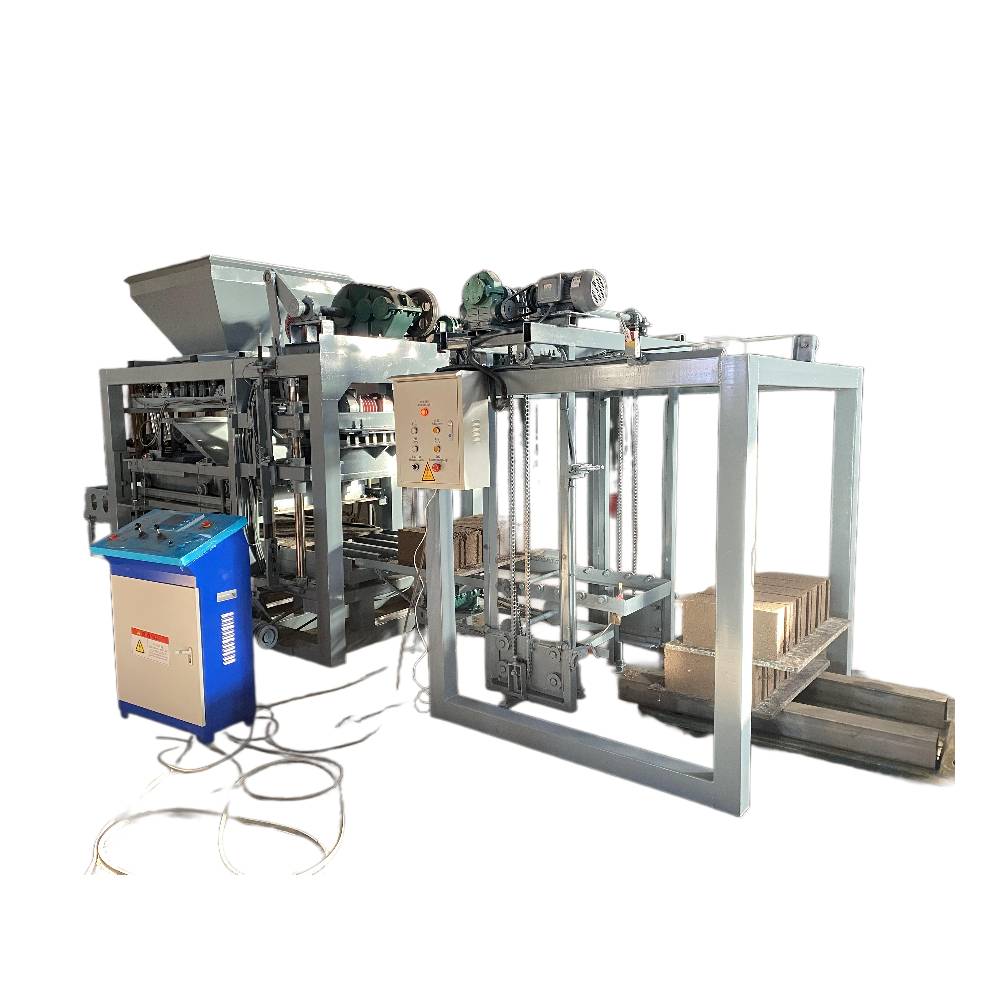

QT4-25 Automatic concrete hollow block machine widely used cement brick making machine for sale is one of our sell best machine model, it is manual type machine, suitable for making all types of hollow blocks, solid block, pavers, curbstones and so on. This machine equiped a larger reducer, its key rotary parts are changed into bearings, thickened square steel frame is used and wear resisting material is adopted for its inside sleeves for directional positioning for four guiding columns so that the service life of this machine can be largely prolonged. With the durable quality, stable running, easy operation and cheaper price attract many customers to buy it.

Product Details

| Heat Treatment Block Mould Use heat treatment and line cutting technology to make sure accurate mold measurements and much longer service life. |  |

| Siemens PLC Station Siemens PLC control station, high reliability, low failure rate, powerful logic processing and data computing capability, long service life |  |

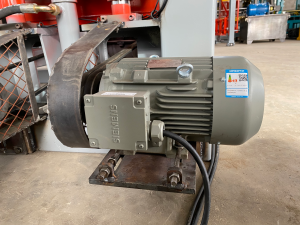

| Siemens Motor German orgrinal Siemens motor, low energy consumption, high protection level, longer service life than normal motors. |  |

Specification

Pallet Size | 880x550mm |

Qty/mold | 4pcs 400x200x200mm |

Host Machine Power | 21kw |

Molding cycle | 25-30s |

Molding method | Vibration |

Host Machine Size | 6400x1500x2700mm |

Host Machine Weight | 3500kg |

Raw materials | Cement, crushed stones, sand, stone powder, slag, fly ash, construction waste etc. |

Block size | Qty/mold | Cycle time | Qty/Hour | Qty/8 hours |

Hollow block 400x200x200mm | 4pcs | 25-30s | 480-576pcs | 3840-4608pcs |

Hollow block 400x150x200mm | 5pcs | 25-30s | 600-720pcs | 4800-5760pcs |

Hollow block 400x100x200mm | 7pcs | 25-30s | 840-1008pcs | 6720-8064pcs |

Solid brick 240x110x70mm | 20pcs | 25-30s | 2400-2880pcs | 19200-23040pcs |

Holland paver 200x100x60mm | 14pcs | 25-30s | 1680-2016pcs | 13440-16128pcs |

Zigzag paver 225x112.5x60mm | 12pcs | 25-30s | 1440-1728pcs | 11520-13824pcs |

Customer Photos

Packing & Delivery

FAQ

- Who are we?

We are based in Hunan, China, start from 1999,sell to Africa(35%), South America(15%), South Asia(15%), Southeast Asia(10.00%), Mid East(5%),North America(5.00%), Eastern Asia(5.00%), Europe(5%),Central America(5%).

What is your pre-sale service?

1.Perfect 7*24 hours inquiry and professional consulting services.

2.Visit our factory anytime.

What is your on-sale service?

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

4.What is your After-Sales

1.Warranty period: 3 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.

5. What payment term and language can you accapt?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

The QT4-25 Automatic Concrete Block Machine is a state-of-the-art solution for manufacturers seeking high productivity and versatility in their operations. This machine stands out in the cement brick making industry, primarily due to its remarkable efficiency and reliability. Engineered with advanced technology, the QT4-25 excels in producing a variety of concrete blocks, including hollow blocks, solid blocks, pavers, and curbstones. Designed to meet the diverse needs of the construction sector, it offers a flexible approach that ensures users can adapt it to various project requirements. Its innovative cement brick making mould allows for precise shaping and consistent quality across batches, making it one of the best-selling models in our lineup. What sets the QT4-25 apart is its user-friendly operation. Despite being a fully automatic machine, it benefits from a manual-type design that simplifies maintenance and reduces the learning curve for new operators. The seamless integration of automation with hands-on control means that both seasoned professionals and newcomers can operate the machine with confidence. Furthermore, the QT4-25 is built with high-quality materials, ensuring longevity and minimizing downtime due to repairs. Investing in this machine not only enhances production capabilities but also contributes to sustainable practices in construction by optimizing resource usage in cement brick making mould processes. Beyond its outstanding performance in block production, the QT4-25 is also designed with energy efficiency in mind. Its optimized drive system reduces power consumption while maintaining powerful output, translating into cost savings for businesses. The machine’s capability to produce different block types with ease makes it ideal for a wide range of applications, from residential construction to large-scale commercial projects. Additionally, our commitment to customer satisfaction means that you will receive comprehensive support, including detailed operational training and ongoing maintenance assistance. Choose the QT4-25 Automatic Concrete Block Machine for reliable production and elevate your construction business with the best in cement brick making mould technology.