Premium LB1500 Asphalt Batching Plant - 120ton Capacity | Concrete Block Machine Manufacturer

Product Description

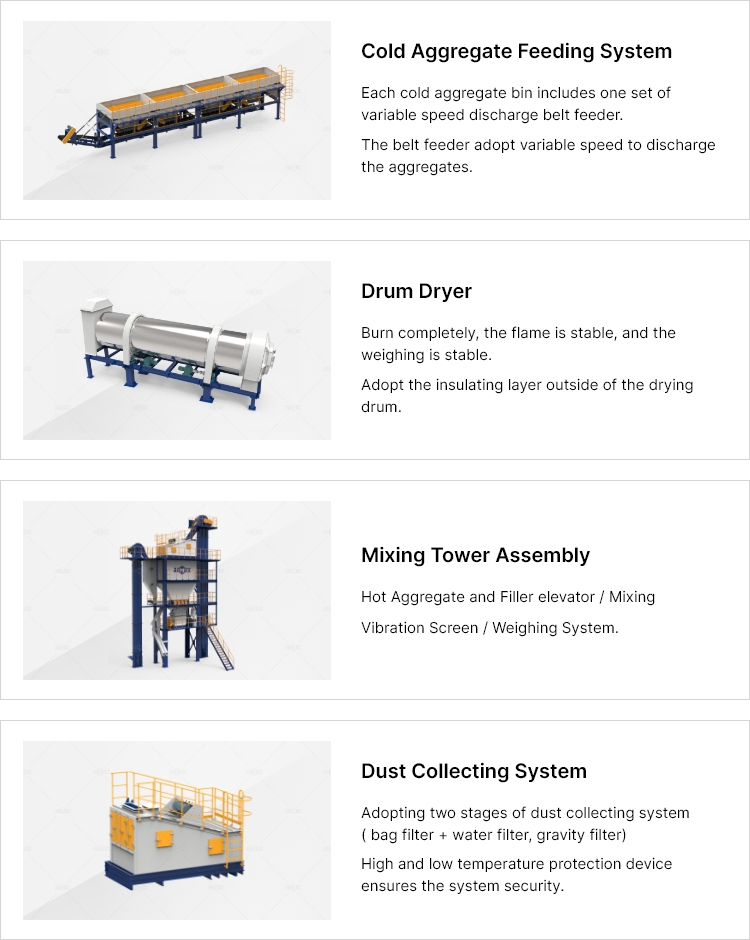

It mainly consists of batching system, drying system, combustion system, hot material lifting, vibrating screen, hot material storage bin, weighing mixing system, asphalt supply system, powder supply system, dust removal system, finished product silo and control system.

Product Details

Main advantages of asphalt concrete mixing plant:

• Cost effective solutions for your project

• Multi-fuel burner for choose

• Environmental protection, energy saving, safe and easy to operate

• Low maintenance operation & Low energy consumption & Low emission

• Optional environmental design - sheeting and clad to customers requirements

• Rational layout, simple foundation, easy to be installed and maintenance

Specification

Model | Rated Output | Mixer Capacity | Dust removal effect | Total power | Fuel consumption | Fire coal | Weighing accuracy | Hopper Capacity | Dryer Size |

SLHB8 | 8t/h | 100kg |

≤20 mg/Nm³

| 58kw |

5.5-7 kg/t

|

10kg/t

| aggregate;±5‰

powder;±2.5‰

asphalt;±2.5‰

| 3×3m³ | φ1.75m×7m |

SLHB10 | 10t/h | 150kg | 69kw | 3×3m³ | φ1.75m×7m | ||||

SLHB15 | 15t/h | 200kg | 88kw | 3×3m³ | φ1.75m×7m | ||||

SLHB20 | 20t/h | 300kg | 105kw | 4×3m³ | φ1.75m×7m | ||||

SLHB30 | 30t/h | 400kg | 125kw | 4×3m³ | φ1.75m×7m | ||||

SLHB40 | 40t/h | 600kg | 132kw | 4×4m³ | φ1.75m×7m | ||||

SLHB60 | 60t/h | 800kg | 146kw | 4×4m³ | φ1.75m×7m | ||||

LB1000 | 80t/h | 1000kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1300 | 100t/h | 1300kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1500 | 120t/h | 1500kg | 325kw | 4×8.5m³ | φ1.75m×7m | ||||

LB2000 | 160t/h | 2000kg | 483kw | 5×12m³ | φ1.75m×7m |

Shipping

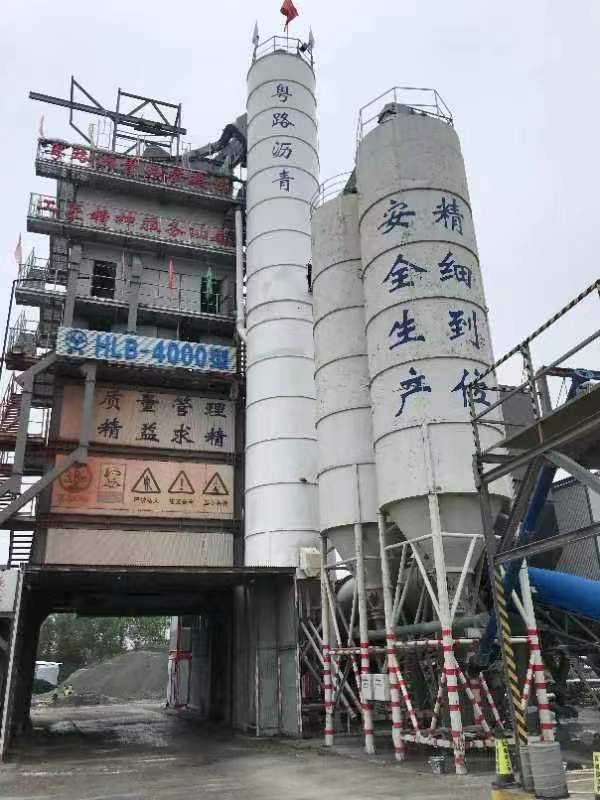

Our Customer

FAQ

- Q1: How to heat the asphalt?

A1: It's heated by heat conducting oil furnace and direct heating asphalt tank.

A2: According to the capacity require per day, need to work how many days, how long destination site, etc.

Q3: What is the delivery time?

A3: 20-40 days after receiving advance payment.

Q4: What are the payment terms?

A4: T/T, L/C, Credit card (for spare parts) are all accept.

Q5: How about after-sale service?

A5: We provide the whole after-sales service system. The warranty period of our machines is one year, and we have professional after-sale service teams to promptly and thoroughly solve your problems.

Introducing the Premium LB1500 Asphalt Batching Plant, a leading solution expertly designed to meet the demands of modern construction projects. With a substantial capacity of 120 tons, this batching plant is engineered for efficiency and reliability. Aichen, a trusted concrete block machine manufacturer, ensures this plant delivers superior performance for all your asphalt production needs. The plant is designed with a comprehensive set of systems including a batching system, drying system, and combustion system that work in harmony to create high-quality asphalt mixtures. Whether you are paving roads, constructing parking lots, or developing any other asphalt-dependent project, the LB1500 will provide the consistency and quality required to get the job done right. The LB1500 integrates advanced technology throughout its design. The hot material lifting system and efficient vibrating screen guarantee that aggregates are processed optimally, enhancing the overall quality of the finished product. With a robust hot material storage bin, you can expect continual operation without interruptions, maximizing productivity on your site. Moreover, Aichen’s commitment to safety and environmental standards is evident in the integrated dust removal system, ensuring a cleaner working environment. As a reputable concrete block machine manufacturer, Aichen prides itself on crafting equipment that meets not only industry standards but also the unique challenges faced by contractors in the field. Additionally, the weighing and mixing system of the LB1500 is designed for precision, ensuring that every batch meets the specifications laid out by your project requirements. The seamless operation of the asphalt supply system and the powder supply system together with the finished product silo facilitates efficient workflow management in busy construction settings. With our user-friendly control system, operators can easily manage and monitor every aspect of the asphalt production process. In choosing the Premium LB1500 Asphalt Batching Plant from Aichen, you are choosing a partner that understands the complexities of the construction industry and is dedicated to providing superior machinery that enhances productivity and reliability. Experience the difference today with Aichen, a leading concrete block machine manufacturer.