Premium LB1500 Asphalt Batching Plant - 120 Ton Capacity, Concrete Block Making Plant Expert

Product Description

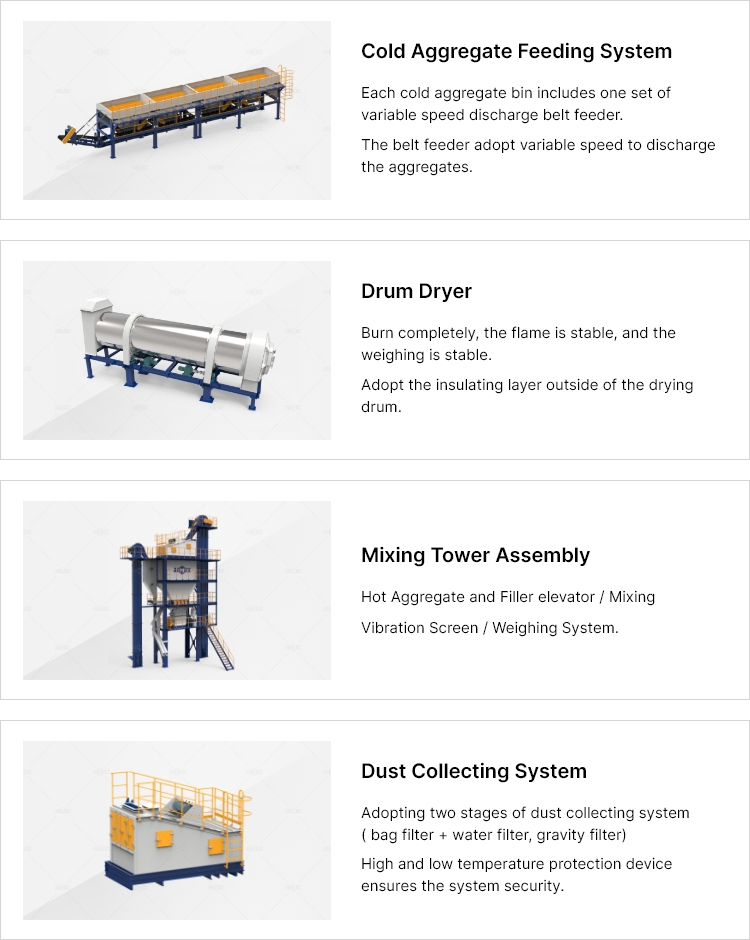

It mainly consists of batching system, drying system, combustion system, hot material lifting, vibrating screen, hot material storage bin, weighing mixing system, asphalt supply system, powder supply system, dust removal system, finished product silo and control system.

Product Details

Main advantages of asphalt concrete mixing plant:

• Cost effective solutions for your project

• Multi-fuel burner for choose

• Environmental protection, energy saving, safe and easy to operate

• Low maintenance operation & Low energy consumption & Low emission

• Optional environmental design - sheeting and clad to customers requirements

• Rational layout, simple foundation, easy to be installed and maintenance

Specification

Model | Rated Output | Mixer Capacity | Dust removal effect | Total power | Fuel consumption | Fire coal | Weighing accuracy | Hopper Capacity | Dryer Size |

SLHB8 | 8t/h | 100kg |

≤20 mg/Nm³

| 58kw |

5.5-7 kg/t

|

10kg/t

| aggregate;±5‰

powder;±2.5‰

asphalt;±2.5‰

| 3×3m³ | φ1.75m×7m |

SLHB10 | 10t/h | 150kg | 69kw | 3×3m³ | φ1.75m×7m | ||||

SLHB15 | 15t/h | 200kg | 88kw | 3×3m³ | φ1.75m×7m | ||||

SLHB20 | 20t/h | 300kg | 105kw | 4×3m³ | φ1.75m×7m | ||||

SLHB30 | 30t/h | 400kg | 125kw | 4×3m³ | φ1.75m×7m | ||||

SLHB40 | 40t/h | 600kg | 132kw | 4×4m³ | φ1.75m×7m | ||||

SLHB60 | 60t/h | 800kg | 146kw | 4×4m³ | φ1.75m×7m | ||||

LB1000 | 80t/h | 1000kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1300 | 100t/h | 1300kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1500 | 120t/h | 1500kg | 325kw | 4×8.5m³ | φ1.75m×7m | ||||

LB2000 | 160t/h | 2000kg | 483kw | 5×12m³ | φ1.75m×7m |

Shipping

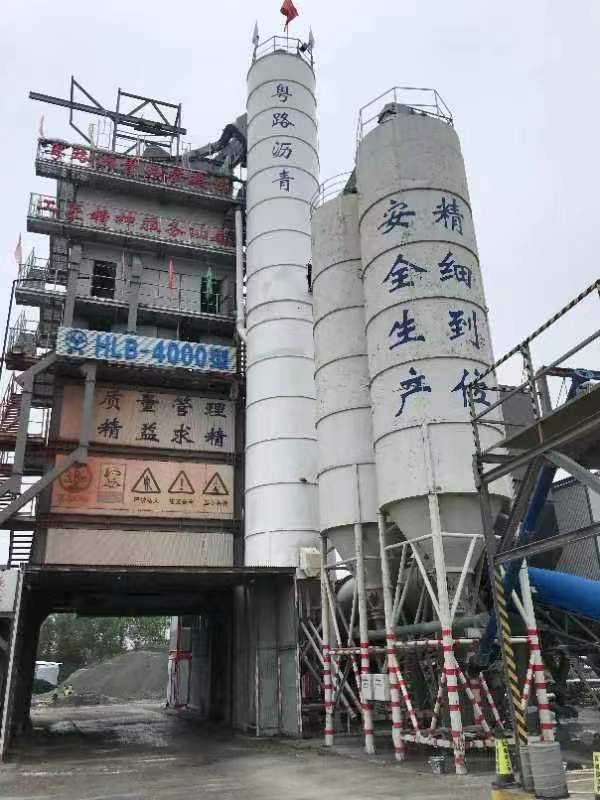

Our Customer

FAQ

- Q1: How to heat the asphalt?

A1: It's heated by heat conducting oil furnace and direct heating asphalt tank.

A2: According to the capacity require per day, need to work how many days, how long destination site, etc.

Q3: What is the delivery time?

A3: 20-40 days after receiving advance payment.

Q4: What are the payment terms?

A4: T/T, L/C, Credit card (for spare parts) are all accept.

Q5: How about after-sale service?

A5: We provide the whole after-sales service system. The warranty period of our machines is one year, and we have professional after-sale service teams to promptly and thoroughly solve your problems.

The Premium LB1500 Asphalt Batching Plant from Aichen is engineered for excellence, offering an optimal solution for those who require a robust concrete block making plant. This state-of-the-art facility stands out with a remarkable 120-ton capacity, making it highly efficient for large-scale asphalt production. Designed with a focus on reliability, the LB1500 is ideal for both novice and experienced contractors seeking to enhance their operations. Its sophisticated batching system precisely measures aggregates to ensure uniformity and quality. This feature is crucial for maintaining high standards in concrete manufacturing, especially in a concrete block making plant. At the heart of the LB1500 is a meticulously designed drying system that guarantees the effective removal of moisture from aggregates, which is vital for achieving a durable and strong asphalt mix. Coupled with an advanced combustion system, the plant maximizes fuel efficiency while minimizing emissions, thus addressing environmental concerns associated with asphalt production. Additionally, the hot material lifting and vibrating screen systems work in tandem to efficiently handle the processed materials, ensuring that your concrete block making plant operates seamlessly. With an integrated hot material storage bin, the LB1500 allows for continuous production, thus enhancing workflow and meeting high demand in the market. The weighing and mixing system within the LB1500 is meticulously calibrated to achieve precise ratios in the production of asphalt, which is crucial for ensuring quality in your final concrete products. Aichen’s asphalt supply system guarantees a steady flow of hot asphalt, while the powder supply system effectively integrates various admixtures needed for specific applications. The dust removal system is designed to maintain a clean working environment, reflecting our commitment to safety and operational efficiency. Finally, the finished product silo ensures that your asphalt is stored securely and ready for immediate use, solidifying Aichen’s LB1500 as a leader in the industry. Whether you are looking to expand your capabilities or establish a new concrete block making plant, the LB1500 is a sound investment that promises reliability and outstanding performance.