The LB800 Granite Asphalt Batching Plant by CHANGSHA AICHEN INDUSTRY AND TRADE CO., LTD. is engineered to deliver outstanding performance in hot mix asphalt production. This state-of-the-art asphalt batching plant is ideal for highway construction and maintenance. Highly efficient and cost-effective, the LB800 boasts a modular structure that allows for fast transportation and easy installation, making it a perfect choice for projects requiring quick setup and operation.

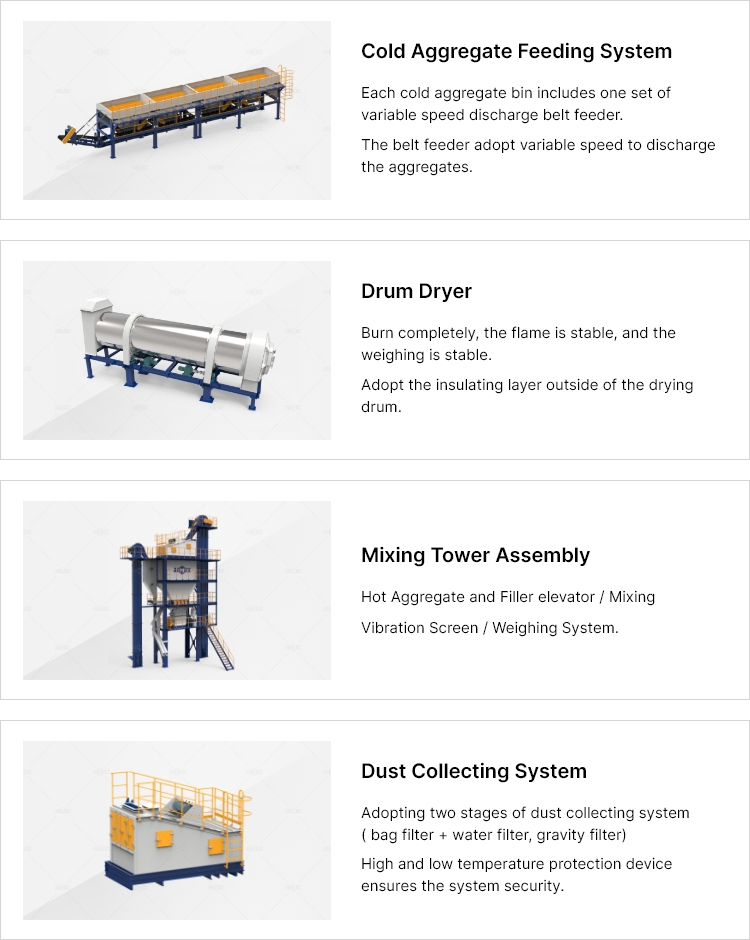

When it comes to the application of an asphalt batching plant, the LB800 stands out with its comprehensive features. The plant’s skirt-type feeding belt ensures a stable and reliable feeding process, which is critical for maintaining the quality of your asphalt mix. Equipped with a plate chain type hot aggregate and powder elevator, the LB800 is designed for durability, extending its service life even under intense operational conditions.

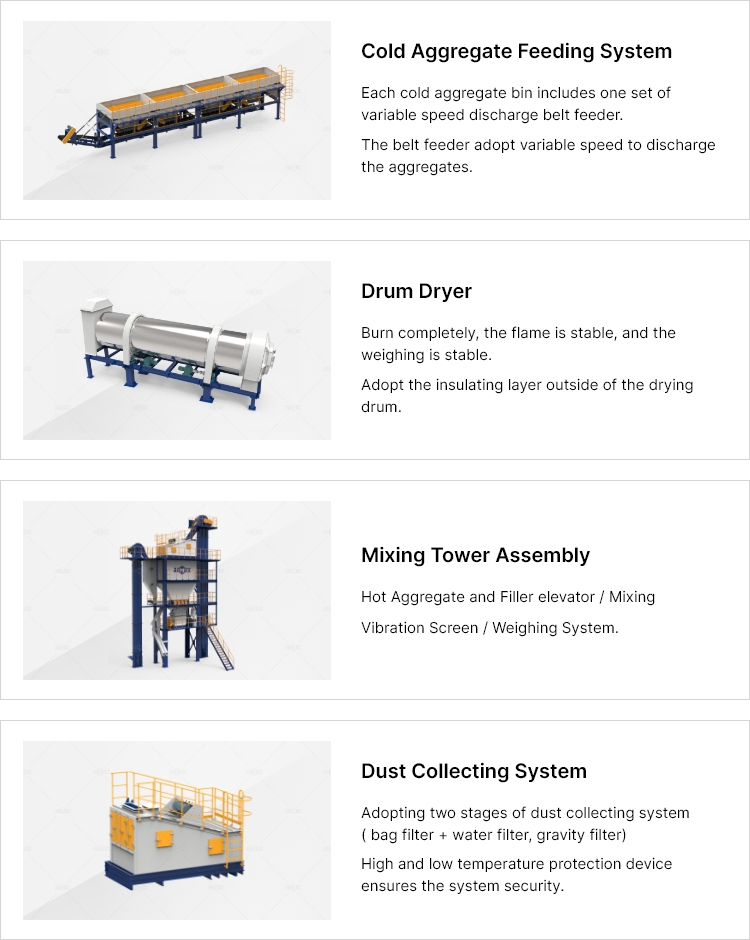

Environmental standards are increasingly crucial in the construction industry, and our LB800 asphalt batching plant excels in this area as well. The inclusion of the world's most advanced pulse bag dust collector significantly reduces emissions to below 20 mg/Nm³, aligning with international environmental standards. This not only helps you meet regulatory requirements but also promotes a greener construction process, allowing you to contribute positively to environmental protection.

CHANGSHA AICHEN’s commitment to quality is evident in the optimized design of the asphalt batching plant. The use of energy-efficient components, including a high energy conversion rate hardened reducer, ensures that the plant operates with minimal power consumption, thereby maximizing economic benefits for users. Along with complying with EU, CE, and GOST (Russian) certifications, the LB800 meets all U.S. and European market requirements for safety, energy conservation, and environmental protection.

As a leading manufacturer and supplier of asphalt batching plants, CHANGSHA AICHEN INDUSTRY AND TRADE CO., LTD. prides itself on delivering products that provide reliable performance and high-quality results. With a rated output of 88t/h and a mixer capacity of 100 kg, the LB800 is designed to meet various project demands. The accuracy of weighing aggregates, powders, and asphalt is within ±5‰ and ±2.5‰, ensuring the integrity of your asphalt mix every time.

Whether you are looking for a stationary model or exploring options for a mobile batching plant, CHANGSHA AICHEN has the expertise and technology to address your needs. Explore our asphalt batching plant solutions today and experience the advantages of partnering with an industry leader. For inquiries or detailed specifications, feel free to contact us.

Staionary asphalt batching plant is a hot mix asphalt plant developed and manufactured by sinoroader in accordance with the needs of the market after absorbing the international advanced technology. Product Description

The mixing plant adopts a modular structure, fast transportation and convenient installation, compact structure, small cover area and high cost performance. The total installed power of the device is low, saving energy, can create considerable economic benefits for the user. The plant features accurate measurement, simple operation and stable performance which fully meets the requirements of highway construction and maintenance.

Product Details

Main advantages of asphalt concrete mixing plant:1. Skirt type feeding belt to ensure more stable and reliable feeding.2. Plate chain type hot aggregate and powder elevator to extend its service life.3. The world's most advanced pulse bag dust collector reduces emission to be below 20mg/Nm3, which meets the international environmental standard.4. Optimized design, while using high energy conversion rate hardened reducer, energy efficient.5. Plants pass through the EU, CE certification and GOST(Russian), which are in full compliance with U.S. and European markets for quality, energy conservation, environmental protection and safety requirements.

CLICK HERE TO CONTACT US

Specification

Model | Rated Output | Mixer Capacity | Dust removal effect | Total power | Fuel consumption | Fire coal | Weighing accuracy | Hopper Capacity | Dryer Size |

SLHB8 | 8t/h | 100kg | ≤20 mg/Nm³ | 58kw | 5.5-7 kg/t | 10kg/t | aggregate;±5‰ powder;±2.5‰ asphalt;±2.5‰ | 3×3m³ | φ1.75m×7m |

SLHB10 | 10t/h | 150kg | 69kw | 3×3m³ | φ1.75m×7m |

SLHB15 | 15t/h | 200kg | 88kw | 3×3m³ | φ1.75m×7m |

SLHB20 | 20t/h | 300kg | 105kw | 4×3m³ | φ1.75m×7m |

SLHB30 | 30t/h | 400kg | 125kw | 4×3m³ | φ1.75m×7m |

SLHB40 | 40t/h | 600kg | 132kw | 4×4m³ | φ1.75m×7m |

SLHB60 | 60t/h | 800kg | 146kw | 4×4m³ | φ1.75m×7m |

LB1000 | 80t/h | 1000kg | 264kw | 4×8.5m³ | φ1.75m×7m |

LB1300 | 100t/h | 1300kg | 264kw | 4×8.5m³ | φ1.75m×7m |

LB1500 | 120t/h | 1500kg | 325kw | 4×8.5m³ | φ1.75m×7m |

LB2000 | 160t/h | 2000kg | 483kw | 5×12m³ | φ1.75m×7m |

Shipping

Our Customer

FAQ

Q1: How to heat the asphalt?

A1: It's heated by heat conducting oil furnace and direct heating asphalt tank.

Q2: How to choose the right machine for project?

A2: According to the capacity require per day, need to work how many days, how long destination site, etc.

Engineers online will provide service to help you choose the right model also.

Q3: What is the delivery time?

A3: 20-40 days after receiving advance payment.

Q4: What are the payment terms?

A4: T/T, L/C, Credit card (for spare parts) are all accept.

Q5: How about after-sale service?

A5: We provide the whole after-sales service system. The warranty period of our machines is one year, and we have professional after-sale service teams to promptly and thoroughly solve your problems.