LB1000 80ton Asphalt Batch Mix Plant – Your Ultimate Hydraulic Cement Brick Making Machine Solution

Product Details

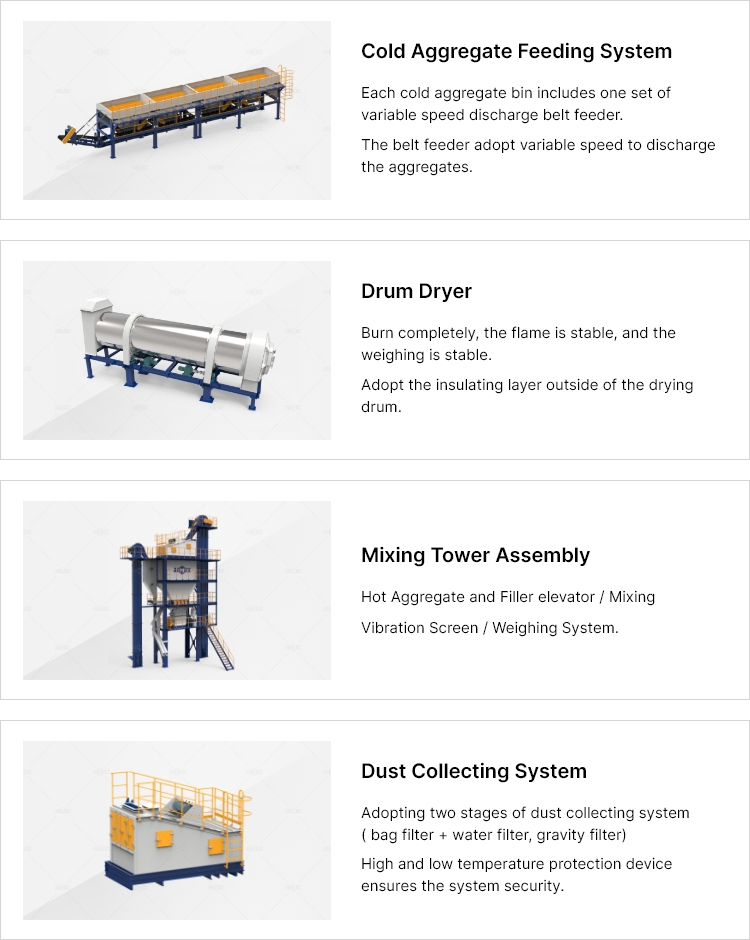

Main Structure

1. Cold Aggregate Feeding System

- The belt feeder use frequency conversion speed control, speed adjust rang is wide, high working efficiency.

- Every hopper discharge gate have material shortage alarming device, if material shortage or material arching, it will alarm automatically.

- On the sand bin, there is vibrator, so it can guarantee normal working.

- There is isolation screen on top of cold bin, so can avoid large material input.

- The conveyor belt use circular belt without joint, steady running and long performance life.

- At the input port of feeding belt conveyor, there is one simple screen can avoid big material input which can enhance hot efficiency and make sure the drying drum, hot aggregate elevator and vibration screen work reliability.

2. Drying System

- The blade geometry of the dryer has been optimized to deliver an exceptionally efficient drying and heating process with reduced energy consumption,improve heating efficiency 30% than conventional design; Because of High heating efficiency, drum surface temperature is relatively low, so the cooling time after operation is considerably shorted.

- Fully insulated and clad aggregate dryer. Drive by electric motors and gear unit through polymer friction drive support rollers.

- Adopt famous brand HONEYWELL temperature intelligent control system.

- Adopt high combustion efficiency Italian brand burner, make sure low exhaust gas emission (like CO2,low No1 & No2, So2).

- Diesel, heavy oil, gas, coal or multi-fuel burners.

3. Vibrating screen

- Improved vibration and amplitude to optimize impact on the available screen.

- Wear-resistant charging system with uniform distribution of the particle mix.

- Wide open doors for easy access and screen meshes are simple to replace, so the down time is reduced.

- The best combination of vibrating direction & screen box dip angle, ensure ratio and screening efficiency.

4. Weighing system

- Adopt famous brand METTLER TELEDO weighing sensor, make sure accurate weighing, in order to make sure the asphalt mixture quality.

5. Mixing system

- Mixer are designed by 3D mixing design, with long arms, shortened shaft diameter and a bi-directional mixing blades array.

- The discharging process has been completely redesigned, the discharge time is minimal.

- The distance between blades and bottom of the mixer is also restrained to the optimal minimum.

- Bitumen is sprayed from multi-points evenly over aggregate by one pressurized bitumen pump to achieve full coverage and high mixing efficiency.

6. Dust Collecting System

- Gravity primary dust collector collecting and recycling bigger fine, saving consumption.

- Bag house secondary dust filter control emission be lower than 20mg/Nm3, eco-friendly.

- Adopt USA Dopont NOMEX filter bags, high temperature resistance and long service life, and the filter bags ban be replaced easily and quickly with no need for special tools.

- Intelligent temperature and control system, when the dust air temperature is higher than set data, cold air valve will be opened automatically for cooling, avoid the filter bags are damaged by high temperature.

- Adopt high voltage pulse cleaning technology, contributing to a lower bag wearing, longer lifespan and better dust removal performance.

Specification

Model | Rated Output | Mixer Capacity | Dust removal effect | Total power | Fuel consumption | Fire coal | Weighing accuracy | Hopper Capacity | Dryer Size |

SLHB8 | 8t/h | 100kg |

≤20 mg/Nm³

| 58kw |

5.5-7 kg/t

|

10kg/t

| aggregate;±5‰

powder;±2.5‰

asphalt;±2.5‰

| 3×3m³ | φ1.75m×7m |

SLHB10 | 10t/h | 150kg | 69kw | 3×3m³ | φ1.75m×7m | ||||

SLHB15 | 15t/h | 200kg | 88kw | 3×3m³ | φ1.75m×7m | ||||

SLHB20 | 20t/h | 300kg | 105kw | 4×3m³ | φ1.75m×7m | ||||

SLHB30 | 30t/h | 400kg | 125kw | 4×3m³ | φ1.75m×7m | ||||

SLHB40 | 40t/h | 600kg | 132kw | 4×4m³ | φ1.75m×7m | ||||

SLHB60 | 60t/h | 800kg | 146kw | 4×4m³ | φ1.75m×7m | ||||

LB1000 | 80t/h | 1000kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1300 | 100t/h | 1300kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1500 | 120t/h | 1500kg | 325kw | 4×8.5m³ | φ1.75m×7m | ||||

LB2000 | 160t/h | 2000kg | 483kw | 5×12m³ | φ1.75m×7m |

Shipping

Our Customer

FAQ

- Q1: How to heat the asphalt?

A1: It's heated by heat conducting oil furnace and direct heating asphalt tank.

A2: According to the capacity require per day, need to work how many days, how long destination site, etc.

Q3: What is the delivery time?

A3: 20-40 days after receiving advance payment.

Q4: What are the payment terms?

A4: T/T, L/C, Credit card (for spare parts) are all accept.

Q5: How about after-sale service?

A5: We provide the whole after-sales service system. The warranty period of our machines is one year, and we have professional after-sale service teams to promptly and thoroughly solve your problems.

The LB1000 80ton Asphalt Batch Mix Plant is engineered to meet the evolving demands of the construction industry, offering an unparalleled blend of efficiency and reliability. This state-of-the-art hydraulic cement brick making machine is designed to produce high-quality asphalt mixtures that meet stringent industry standards. With an impressive production capacity of 80 tons per hour, the LB1000 plant ensures that construction projects can be completed on time and within budget, making it an indispensable asset for contractors and builders alike. Its advanced technological features not only optimize performance but also enhance the quality of outputs, ensuring that every batch meets the necessary specifications for paving, road construction, and other critical applications. The robust design of the LB1000 includes a highly efficient mixing system that guarantees uniform blending of materials, which is crucial for producing durable asphalt. The plant's hydraulic system plays a pivotal role in the operational efficiency of this hydraulic cement brick making machine. It facilitates smooth and precise control of the mixing process, resulting in consistent product quality with minimal waste. Additionally, the LB1000 is equipped with environmentally friendly features that minimize emissions and energy consumption, making it a responsible choice for modern construction practices. The user-friendly interface allows operators to monitor and control the production process effortlessly, further enhancing operational efficiency. In addition to its impressive performance metrics, the LB1000 80ton Asphalt Batch Mix Plant is designed for ease of maintenance and longevity. The materials used in its construction are selected for their durability and resilience, ensuring that the plant can withstand the rigors of daily use in demanding environments. By choosing this hydraulic cement brick making machine, you are investing in a reliable solution that will not only meet your immediate production needs but also serve your business in the long run. The LB1000 is the perfect choice for those looking to elevate their construction capabilities while maintaining a commitment to quality and performance. With Aichen's commitment to innovation and excellence, the LB1000 is set to become a cornerstone of your construction operations.