Hydraulic Fully Automatic Machine Block Making - QT4-16 by CHANGSHA AICHEN

QT4-15 adopts full automatic spiral material laying method, the material in the mould is well-distributed. It's easy operation and high productivity, when producing blocks.

Product Description

1) Full automatic block making machine

2) Adopt Japan Omron and France Schneider brand switches, Siemens and ABB brand motors

3) Precise line cutting technology and carburizing treatment technology to promote mould life and precision of the block

4) Reasonable raw material ratio can produce high strength standard brick, after forming, can stack immediately

5) PLC control system made by Japan Mitsubishi brand, assure stable and high efficiency working status

Product Details

| Heat Treatment Block Mould Use heat treatment and line cutting technology to make sure accurate mold measurements and much longer service life. |  |

| Siemens PLC Station Siemens PLC control station, high reliability, low failure rate, powerful logic processing and data computing capability, long service life |  |

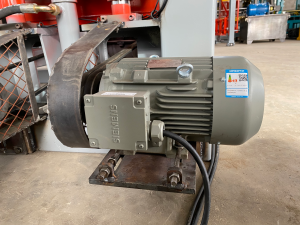

| Siemens Motor German orgrinal Siemens motor, low energy consumption, high protection level, longer service life than normal motors. |  |

Specification

Pallet Size | 900x550mm |

Qty/mold | 4pcs 400x200x200mm |

Host Machine Power | 27kw |

Molding cycle | 15-25s |

Molding method | Vibration+Hydraulic pressure |

Host Machine Size | 3900x2400x2800mm |

Host Machine Weight | 5000kg |

Raw materials | Cement, crushed stones, sand, stone powder, slag, fly ash, construction waste etc. |

Block size | Qty/mold | Cycle time | Qty/Hour | Qty/8 hours |

Hollow block 400x200x200mm | 4 pcs | 15-20s | 720-960pcs | 5760-7680pcs |

Hollow block 400x150x200mm | 5pcs | 15-20s | 900-1200pcs | 7200-9600pcs |

Hollow block 400x100x200mm | 7pcs | 15-20s | 1260-1680pcs | 10080-13440pcs |

Solid brick 240x110x70mm | 20pcs | 15-20s | 3600-4800pcs | 28800-38400pcs |

Holland paver 200x100x60mm | 14pcs | 15-25s | 2016-3360pcs | 16128-26880pcs |

Zigzag paver 225x112.5x60mm | 12pcs | 15-20s | 1728-2880pcs | 13824-23040pcs |

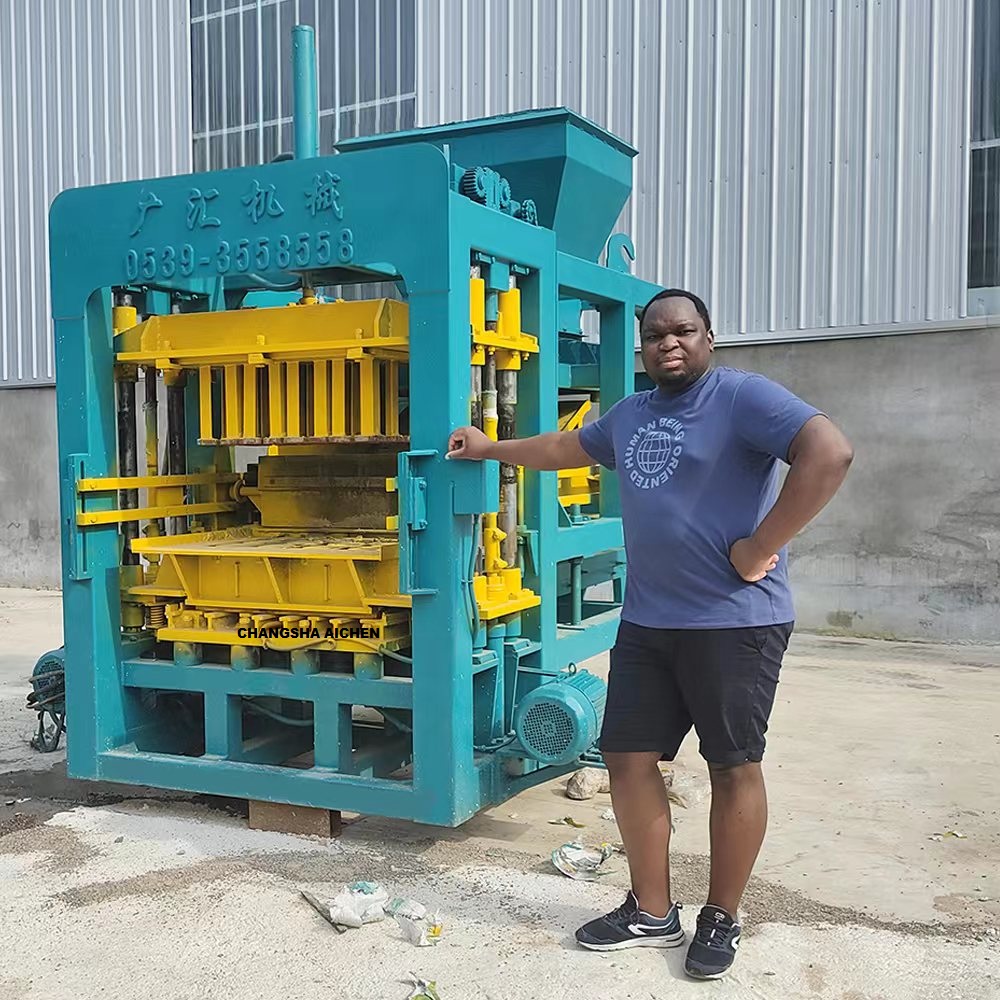

Customer Photos

Packing & Delivery

FAQ

- Who are we?

We are based in Hunan, China, start from 1999,sell to Africa(35%), South America(15%), South Asia(15%), Southeast Asia(10.00%), Mid East(5%),North America(5.00%), Eastern Asia(5.00%), Europe(5%),Central America(5%).

What is your pre-sale service?

1.Perfect 7*24 hours inquiry and professional consulting services.

2.Visit our factory anytime.

What is your on-sale service?

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

4.What is your After-Sales

1.Warranty period: 3 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.

5. What payment term and language can you accapt?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

Introducing the Hydraulic Fully Automatic Block Making Machine - QT4-16 by CHANGSHA AICHEN, a pinnacle of modern engineering designed to revolutionize your machine block making operations. Our innovative machine is equipped with cutting-edge features that ensure not only high productivity but also exceptional precision in every block produced. With a full automation system, this machine significantly reduces labor costs while maximizing output efficiency. The integration of Japan's Omron and France's Schneider brand switches, along with reliable Siemens and ABB brand motors, guarantees safety and dependability in various working conditions. One of the standout features of our QT4-16 model is the implementation of precise line cutting technology coupled with advanced carburizing treatment. This state-of-the-art process enhances the lifespan of the molds and allows for remarkable accuracy in block dimensions. The molds are designed to withstand rigorous use while retaining their effectiveness over extended production cycles. Utilizing a carefully formulated raw material ratio, this machine can produce high-strength standard bricks that meet industry standards. Moreover, it allows for immediate stacking post-formation, thereby speeding up the production workflow and enhancing operational efficiency. At the heart of the QT4-16 is a sophisticated PLC control system engineered by Japan's Mitsubishi brand. This intelligent system ensures a stable and high-efficiency working environment, allowing for seamless operations and minimal downtime. The user-friendly interface simplifies the monitoring and adjustment of production parameters, making it easier for operators to optimize the machine block making process. By choosing the Hydraulic Fully Automatic Block Making Machine - QT4-16 by CHANGSHA AICHEN, you're investing in a reliable, efficient solution that pushes the boundaries of automated block production. Experience the future of machine block making today with our advanced technology and commitment to quality.