High-Quality Automatic Egglaying Block Machine - Perfect Machine to Make Cement Blocks

QTM6-30 egg laying block machine can produce different shapes blocks, bricks and pavers by changing mould, can ensure the block quality very good and movable using.

Product Description

1. Has greater productivity than other small block making machines. This brick machine is based on the original block forming machine produced by our company, combined with foreign advanced technology and real on-site use feedback from customers over the years, and integrated our company's many years of mobile brick machine manufacturing experience. It is a relatively mature model. This mobile brick machine has more reasonable design, easy operation, high forming rate, low maintenance rate, low noise, low energy consumption and many other advantages. It is ahead of other domestic The same type of mobile brick machine.

2. The advanced technology makes the design of the main engine reasonable, and realizes the vibration of the box, hydraulic demoulding, electric walking, and auxiliary steering, which can be easily mastered by one person. High-quality steel and precision welding make the machine last longer.

3. It has the features of low price, reliable performance, convenient operation, stability, low power consumption (only one-fifth of the power consumption of the machine with the same output power), raw materials, concrete, cement, small stones can be used in the production process, Stone powder, sand, slag, construction waste, etc.

Product Details

| Heat Treatment Block Mould Use heat treatment and line cutting technology to make sure accurate mold measurements and much longer service life. |  |

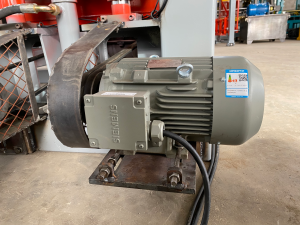

| Siemens PLC Station Siemens PLC control station, high reliability, low failure rate, powerful logic processing and data computing capability, long service life |  |

| Siemens Motor German orgrinal Siemens motor, low energy consumption, high protection level, longer service life than normal motors. |  |

Specification

Size | 2000x2100x1750mm |

Power | 7.5kw |

Weight | 2300kg |

Molding cycle | 15-20s |

Molding method | Hydraulic + Vibration |

Hydraulic pressure | 12-14mpa |

Vibration force | 35.5kn |

Vibration Frequency | 2980 times/minute |

Qty/mold | 6pcs 400x200x200mm |

Raw material | Cement, crushed stones, sand, stone power, slag, fly ash, construction waste etc. |

Block size | Qty/mold | Cycle time | Qty/Hour | Qty/8 hours |

Hollow block 400x200x200mm | 6pcs | 25-30s | 720-864pcs | 5760-6912pcs |

Hollow block 400x150x200mm | 7pcs | 25-30s | 840-1008pcs | 6720-8064pcs |

Hollow block 400x125x200mm | 9pcs | 25-30s | 1080-1300pcs | 8640-10400pcs |

Hollow block 400x100x200mm | 11pcs | 25-30s | 1320-1584pcs | 10560-12672pcs |

Customer Photos

Packing & Delivery

FAQ

- Who are we?

We are based in Hunan, China, start from 1999,sell to Africa(35%), South America(15%), South Asia(15%), Southeast Asia(10.00%), Mid East(5%),North America(5.00%), Eastern Asia(5.00%), Europe(5%),Central America(5%).

What is your pre-sale service?

1.Perfect 7*24 hours inquiry and professional consulting services.

2.Visit our factory anytime.

What is your on-sale service?

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

4.What is your After-Sales

1.Warranty period: 3 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.

5. What payment term and language can you accapt?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

Introducing the High-Quality Automatic Egglaying Block Machine QTM6-30 by CHANGSHA AICHEN, a revolutionary solution designed specifically for businesses aiming to enhance their production capabilities in the construction sector. This state-of-the-art machine to make cement blocks combines top-notch engineering with advanced technology to deliver impressive results in the manufacturing of concrete blocks. With its automatic egg-laying design, this machine operates efficiently, allowing for the seamless production of high-quality cement blocks that meet industry standards. Ideal for both small and large scale operations, the QTM6-30 is designed to maximize productivity while minimizing labor costs, making it an essential asset for your construction business. Equipped with a powerful hydraulic system, the QTM6-30 ensures that each block is compacted to perfection, resulting in strong, durable products that can withstand various environmental conditions. This machine to make cement blocks is not only easy to operate, but it also features user-friendly controls that allow for quick adjustments and troubleshooting. Additionally, the QTM6-30 comes with an intuitive interface that guides operators through the production process, reducing the learning curve and enhancing efficiency. Whether you are producing hollow blocks, solid blocks, or interlocking bricks, this versatile machine can be easily configured to meet your specific needs, providing flexibility to adapt to various construction projects. Furthermore, the High-Quality Automatic Egglaying Block Machine QTM6-30 is designed with durability and reliability in mind. Constructed from high-grade materials, it promises an extended lifespan with minimal maintenance requirements. The robust design ensures that the machine can withstand the rigors of daily operations, making it a wise investment for your business. Moreover, the compact layout of the QTM6-30 allows for easy integration into existing production lines without requiring significant alterations to your workshop layout. By choosing our machine to make cement blocks, you are not only enhancing the quality of your products but also contributing to sustainable construction practices by maximizing resource efficiency and minimizing waste. Embrace the future of block production with CHANGSHA AICHEN’s cutting-edge technology!