20Ton Asphalt Batching Plant | Reliable Asphalt Mixer | Affordable Concrete Block Manufacturing Plant Cost

Product Description

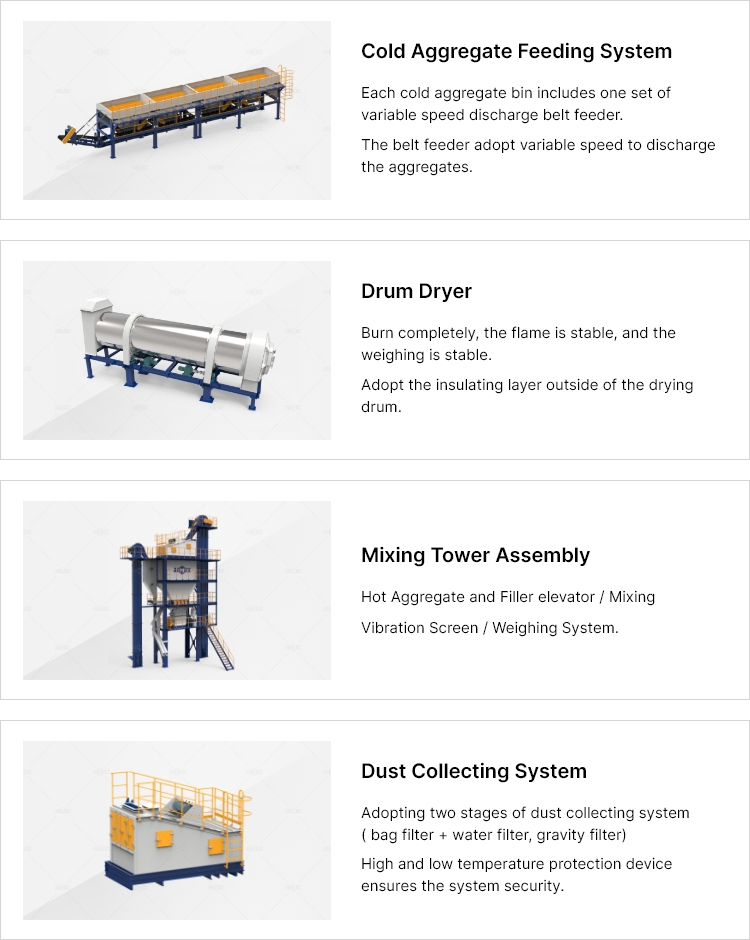

Asphalt Batching Plant, also called asphalt mixing plants or hot mix plants, are equipment that can combine aggregates and bitumen to produce asphalt mix for road paving.

Product Details

Main advantages of asphalt concrete mixing plant:

• Cost effective solutions for your project

• Multi-fuel burner for choose

• Environmental protection, energy saving, safe and easy to operate

• Low maintenance operation & Low energy consumption & Low emission

• Optional environmental design - sheeting and clad to customers requirements

• Rational layout, simple foundation, easy to be installed and maintenance

Specification

Model | Rated Output | Mixer Capacity | Dust removal effect | Total power | Fuel consumption | Fire coal | Weighing accuracy | Hopper Capacity | Dryer Size |

SLHB8 | 8t/h | 100kg |

≤20 mg/Nm³

| 58kw |

5.5-7 kg/t

|

10kg/t

| aggregate;±5‰

powder;±2.5‰

asphalt;±2.5‰

| 3×3m³ | φ1.75m×7m |

SLHB10 | 10t/h | 150kg | 69kw | 3×3m³ | φ1.75m×7m | ||||

SLHB15 | 15t/h | 200kg | 88kw | 3×3m³ | φ1.75m×7m | ||||

SLHB20 | 20t/h | 300kg | 105kw | 4×3m³ | φ1.75m×7m | ||||

SLHB30 | 30t/h | 400kg | 125kw | 4×3m³ | φ1.75m×7m | ||||

SLHB40 | 40t/h | 600kg | 132kw | 4×4m³ | φ1.75m×7m | ||||

SLHB60 | 60t/h | 800kg | 146kw | 4×4m³ | φ1.75m×7m | ||||

LB1000 | 80t/h | 1000kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1300 | 100t/h | 1300kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1500 | 120t/h | 1500kg | 325kw | 4×8.5m³ | φ1.75m×7m | ||||

LB2000 | 160t/h | 2000kg | 483kw | 5×12m³ | φ1.75m×7m |

Shipping

Our Customer

FAQ

- Q1: How to heat the asphalt?

A1: It's heated by heat conducting oil furnace and direct heating asphalt tank.

A2: According to the capacity require per day, need to work how many days, how long destination site, etc.

Q3: What is the delivery time?

A3: 20-40 days after receiving advance payment.

Q4: What are the payment terms?

A4: T/T, L/C, Credit card (for spare parts) are all accept.

Q5: How about after-sale service?

A5: We provide the whole after-sales service system. The warranty period of our machines is one year, and we have professional after-sale service teams to promptly and thoroughly solve your problems.

The 20Ton Asphalt Batching Plant from CHANGSHA AICHEN is engineered to deliver exceptional performance and reliability in asphalt production. This top-tier asphalt mixer combines aggregates and bitumen with precision, ensuring that the asphalt mix adheres to the highest standards for road paving and construction projects. With its robust design, this batching plant stands ready to meet the demands of various applications, whether in urban settings or expansive highway projects. Investing in a 20Ton Asphalt Batching Plant is not merely about purchasing machinery; it's about enhancing the operational capacity of your business. With this plant, you can efficiently produce quality asphalt mixes while keeping costs manageable. The notable aspect of our offering is its competitive concrete block manufacturing plant cost, which allows businesses to optimize their budgets without compromising on quality. This plant’s cutting-edge technology and user-friendly controls make it an ideal choice for companies looking to streamline their operations and achieve greater productivity. Moreover, the 20Ton Asphalt Batching Plant boasts a variety of features that cater to the evolving needs of the construction industry. Its advanced mixing capabilities ensure uniform consistency in asphalt production, reducing waste and increasing efficiency. The plant is designed with durability in mind, allowing it to withstand challenging conditions while delivering consistent results. When considering a concrete block manufacturing plant cost, the longevity and reliability of the Aichen batching plant represents an invaluable investment for any asphalt contractor or construction firm aiming for excellence in their paving projects.