10Ton Asphalt Batching Plant - Leading Block Making Machine Manufacturers

Product Description

- “one-trailer-mounted ” continuous asphalt mixing plant is optimized and redesigned based on our stationary continuous asphalt mixing station

and semi-mobile continuous asphalt mixing station.

- “one-trailer-mounted ” continuous asphalt mixing plant realizes the high integration of asphalt plant, and one transport trailer can realize

all the functional requirements of the asphalt mixing station (filling, drying, mixing, storage of finished products, operation),

which meets the user's requirements for fast installation, fast transition, and rapid production.

- Up to now, our “one-trailer-mounted ” continuous asphalt mixing plant” has been exported to Europe, Africa, North America etc.

The convenience of fast transportation, transfer, and rapid recommissioning greatly saves the costs and improves the construction efficiency.

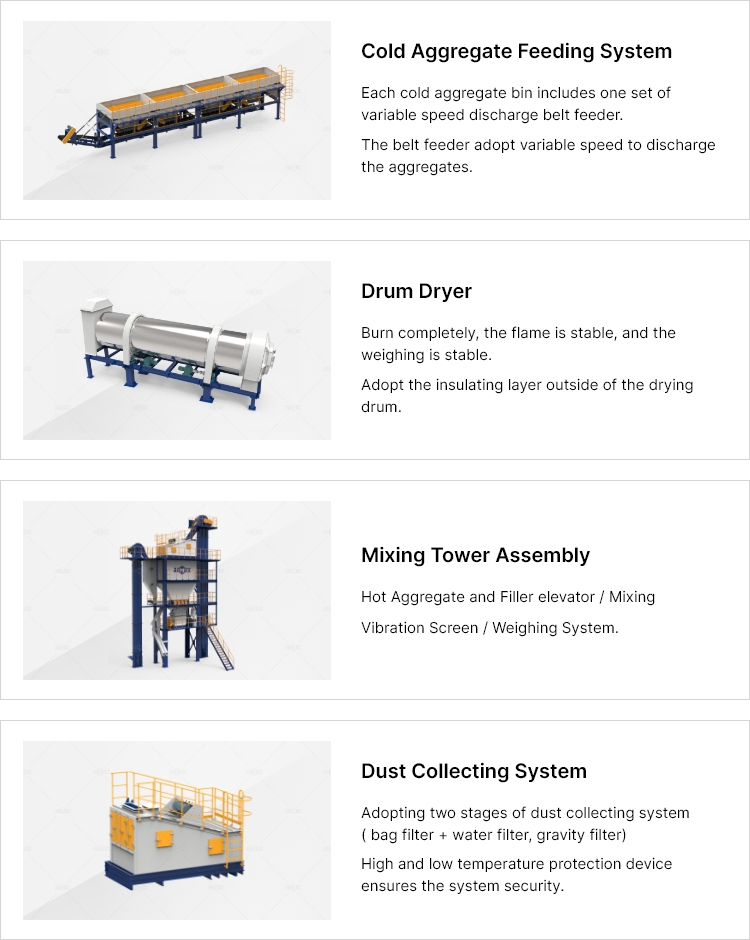

Product Details

Main advantages of asphalt concrete mixing plant:

• Cost effective solutions for your project

• Multi-fuel burner for choose

• Environmental protection, energy saving, safe and easy to operate

• Low maintenance operation & Low energy consumption & Low emission

• Optional environmental design - sheeting and clad to customers requirements

• Rational layout, simple foundation, easy to be installed and maintenance

Specification

Model | Rated Output | Mixer Capacity | Dust removal effect | Total power | Fuel consumption | Fire coal | Weighing accuracy | Hopper Capacity | Dryer Size |

SLHB8 | 8t/h | 100kg |

≤20 mg/Nm³

| 58kw |

5.5-7 kg/t

|

10kg/t

| aggregate;±5‰

powder;±2.5‰

asphalt;±2.5‰

| 3×3m³ | φ1.75m×7m |

SLHB10 | 10t/h | 150kg | 69kw | 3×3m³ | φ1.75m×7m | ||||

SLHB15 | 15t/h | 200kg | 88kw | 3×3m³ | φ1.75m×7m | ||||

SLHB20 | 20t/h | 300kg | 105kw | 4×3m³ | φ1.75m×7m | ||||

SLHB30 | 30t/h | 400kg | 125kw | 4×3m³ | φ1.75m×7m | ||||

SLHB40 | 40t/h | 600kg | 132kw | 4×4m³ | φ1.75m×7m | ||||

SLHB60 | 60t/h | 800kg | 146kw | 4×4m³ | φ1.75m×7m | ||||

LB1000 | 80t/h | 1000kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1300 | 100t/h | 1300kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1500 | 120t/h | 1500kg | 325kw | 4×8.5m³ | φ1.75m×7m | ||||

LB2000 | 160t/h | 2000kg | 483kw | 5×12m³ | φ1.75m×7m |

Shipping

Our Customer

FAQ

- Q1: How to heat the asphalt?

A1: It's heated by heat conducting oil furnace and direct heating asphalt tank.

A2: According to the capacity require per day, need to work how many days, how long destination site, etc.

Q3: What is the delivery time?

A3: 20-40 days after receiving advance payment.

Q4: What are the payment terms?

A4: T/T, L/C, Credit card (for spare parts) are all accept.

Q5: How about after-sale service?

A5: We provide the whole after-sales service system. The warranty period of our machines is one year, and we have professional after-sale service teams to promptly and thoroughly solve your problems.

Introducing the 10Ton Asphalt Batching Plant, a remarkable innovation from CHANGSHA AICHEN, recognized as a leading choice among block making machine manufacturers. This state-of-the-art equipment has been meticulously optimized and redesigned, incorporating the best features of our proven stationary and semi-mobile continuous asphalt mixing stations. With a robust one-trailer-mounted design, this asphalt batching plant offers unparalleled convenience and mobility, making it the perfect solution for various construction projects, especially those demanding high efficiency and reliability. Our product stands out in the marketplace, not only due to its superior engineering but also because of its user-friendly operation and low maintenance requirements. By focusing on the needs of the modern construction industry, we have created a batching plant that easily adapts to different operational contexts, whether it’s for road construction, airport runways, or large-scale civil engineering projects. Thanks to our expertise as block making machine manufacturers, we understand what our clients need: a consistent and high-quality asphalt mix that can withstand the rigors of demanding applications. The 10Ton Asphalt Batching Plant ensures that every batch meets stringent quality standards, thereby maximizing project efficiency and reducing waste. Incorporating advanced technology, our 10Ton Asphalt Batching Plant features automated control systems that simplify the mixing process, allowing for precise adjustments and real-time monitoring. It not only enhances the quality of the asphalt produced but also reduces operational costs throughout the lifecycle of the plant. As reputable block making machine manufacturers, we prioritize sustainability, incorporating eco-friendly practices that minimize emissions and energy consumption. This commitment to innovation and quality positions CHANGSHA AICHEN as a trusted partner in your construction ventures, ensuring that you achieve unmatched performance in every project. Invest in our 10Ton Asphalt Batching Plant today and experience the expertise that sets us apart in the industry.