10 Ton Asphalt Batching Plant - Leading Bitumen Production Plant Manufacturer

Product Description

- “one-trailer-mounted ” continuous asphalt mixing plant is optimized and redesigned based on our stationary continuous asphalt mixing station

and semi-mobile continuous asphalt mixing station.

- “one-trailer-mounted ” continuous asphalt mixing plant realizes the high integration of asphalt plant, and one transport trailer can realize

all the functional requirements of the asphalt mixing station (filling, drying, mixing, storage of finished products, operation),

which meets the user's requirements for fast installation, fast transition, and rapid production.

- Up to now, our “one-trailer-mounted ” continuous asphalt mixing plant” has been exported to Europe, Africa, North America etc.

The convenience of fast transportation, transfer, and rapid recommissioning greatly saves the costs and improves the construction efficiency.

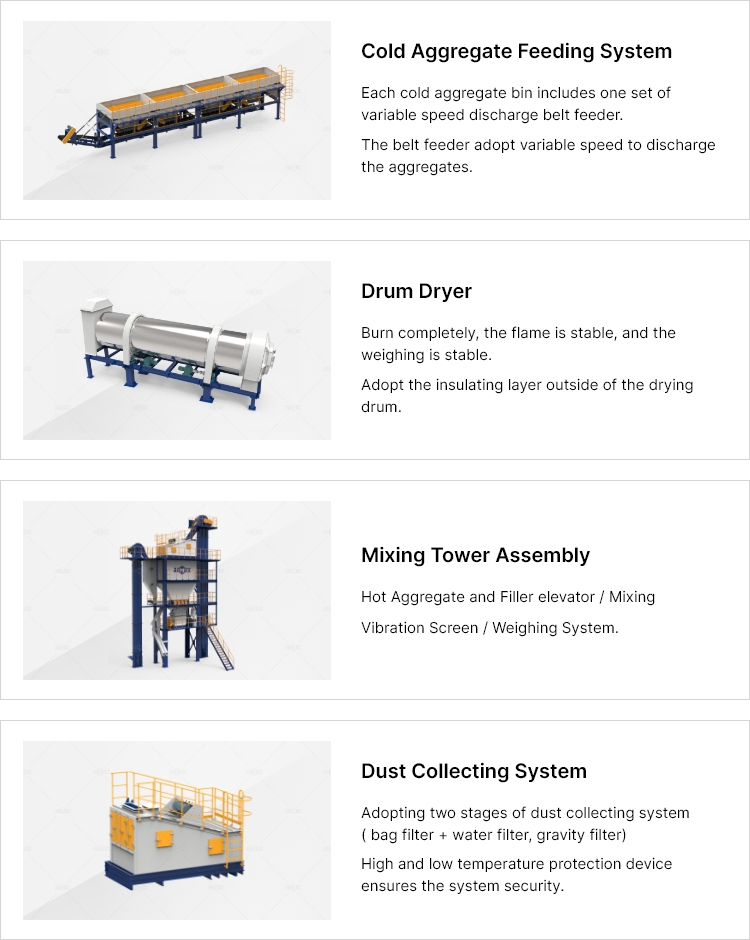

Product Details

Main advantages of asphalt concrete mixing plant:

• Cost effective solutions for your project

• Multi-fuel burner for choose

• Environmental protection, energy saving, safe and easy to operate

• Low maintenance operation & Low energy consumption & Low emission

• Optional environmental design - sheeting and clad to customers requirements

• Rational layout, simple foundation, easy to be installed and maintenance

Specification

Model | Rated Output | Mixer Capacity | Dust removal effect | Total power | Fuel consumption | Fire coal | Weighing accuracy | Hopper Capacity | Dryer Size |

SLHB8 | 8t/h | 100kg |

≤20 mg/Nm³

| 58kw |

5.5-7 kg/t

|

10kg/t

| aggregate;±5‰

powder;±2.5‰

asphalt;±2.5‰

| 3×3m³ | φ1.75m×7m |

SLHB10 | 10t/h | 150kg | 69kw | 3×3m³ | φ1.75m×7m | ||||

SLHB15 | 15t/h | 200kg | 88kw | 3×3m³ | φ1.75m×7m | ||||

SLHB20 | 20t/h | 300kg | 105kw | 4×3m³ | φ1.75m×7m | ||||

SLHB30 | 30t/h | 400kg | 125kw | 4×3m³ | φ1.75m×7m | ||||

SLHB40 | 40t/h | 600kg | 132kw | 4×4m³ | φ1.75m×7m | ||||

SLHB60 | 60t/h | 800kg | 146kw | 4×4m³ | φ1.75m×7m | ||||

LB1000 | 80t/h | 1000kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1300 | 100t/h | 1300kg | 264kw | 4×8.5m³ | φ1.75m×7m | ||||

LB1500 | 120t/h | 1500kg | 325kw | 4×8.5m³ | φ1.75m×7m | ||||

LB2000 | 160t/h | 2000kg | 483kw | 5×12m³ | φ1.75m×7m |

Shipping

Our Customer

FAQ

- Q1: How to heat the asphalt?

A1: It's heated by heat conducting oil furnace and direct heating asphalt tank.

A2: According to the capacity require per day, need to work how many days, how long destination site, etc.

Q3: What is the delivery time?

A3: 20-40 days after receiving advance payment.

Q4: What are the payment terms?

A4: T/T, L/C, Credit card (for spare parts) are all accept.

Q5: How about after-sale service?

A5: We provide the whole after-sales service system. The warranty period of our machines is one year, and we have professional after-sale service teams to promptly and thoroughly solve your problems.

The 10 Ton Asphalt Batching Plant from CHANGSHA AICHEN is a state-of-the-art bitumen production plant that sets the standard for quality and efficiency in the asphalt mixing industry. Built for both reliability and performance, this innovative plant is designed to meet the rigorous demands of modern road construction projects. Our continuous asphalt mixing plant, which is trailer-mounted for ease of transportation, has been meticulously optimized and redesigned. This enhancement is based on our extensive experience with stationary and semi-mobile continuous asphalt mixing stations, ensuring that our customers receive a product that excels in functionality and durability. What makes our 10 Ton bitumen production plant stand out is its ability to produce high-quality asphalt consistently, making it an ideal choice for contractors and construction companies. By utilizing advanced technology and engineering, the plant minimizes downtime and maximizes output. Its continuous mixing capability allows for the efficient blending of aggregates, bitumen, and additives, resulting in superior asphalt mixtures that adhere to strict quality standards. The user-friendly interface and automated controls simplify operation, enabling operators to monitor and adjust the mixing process easily, ultimately enhancing productivity on-site. At CHANGSHA AICHEN, we understand the importance of sustainability and efficiency in any construction project. Our 10 Ton Asphalt Batching Plant is designed with eco-friendliness in mind, incorporating features that reduce waste and energy consumption. Whether you're involved in large infrastructure projects or smaller paving jobs, this bitumen production plant provides the scalability and versatility needed to deliver outstanding results. Choose Aichen for your asphalt mixing solutions, where quality, efficiency, and innovation come together to support your construction goals.